Water towers are used by many communities to provide a reliable water supply during peak usage hours and power outages. These elevated structures are deliberately tall in stature to maintain sufficient pressure to deliver potable water by gravity through a pump distribution network that supplies water to homes.

As residential water pressure requirements range between 45 and 80 psi, the average height of a water tower must be around 165 ft. to deliver water at pressures between 50-60 psi. Municipalities must monitor the water distribution system to ensure proper pressure and water levels. Pressure management is critical as too high or low-pressure levels could result in inefficient system operations and damaged pumps.

Remote sensor control systems eliminate the need for operators to climb towers or travel to various locations to read gauges in monitoring pressure sensors and inputting information into a computer for analysis. However, the operating environment of the water distribution system poses challenges for wired monitoring systems.

When operating in outside environments, wired systems are susceptible to lighting strikes and ground faults that can destroy sensors and everything wired to it. Power also can be a problem for wired systems because only 120V AC is typically available at the water tanks. And as wired systems require that each sensor be wired back to the controller and connected to an interface port, maintenance on hardwired sensors can be costly because of the water tower height.

Wireless Sensing & Monitoring For Reliable Operations

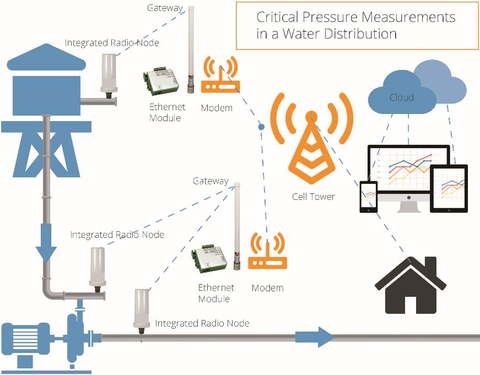

A wireless remote monitoring and control system resembles the architecture of a wired system by using “air wires” instead of cabling to measure and transmit the water pressure of the water tower to a remote location. The wireless telemetry system consists of end nodes that include a radio that powers sensors, which conduct the pressure measurements for transmission to a gateway. Powered by battery, the end nodes address the challenges of using sensors in areas without a power source or when power is unstable.Serving as the central hub for receiving measurements, the gateway stores recent sensor readings in Modbus format for accessibility by a PLC in a control center or through an Internet connection. The gateway can be physically wired to a PLC/SCADA/DCS or wirelessly connected using cell modems. By using 900mHz instead of 2.4gHz, the wireless network provides for robust data transmissions through different terrain, structures, and weather conditions and operates for years in harsh environmental conditions. As nodes and other components are not physically wired, the wireless system reduces the risk of failure due to lightning strikes and ground faults that can destroy wired systems.

In figure 2 below, the Pressure Scout wireless pressure transmitter integrates a wireless radio, pressure sensor, and intrinsically-safe circuitry including a battery to serve as a cost-effective alternative to conduit, wired, and other pressure sensor solutions. This telemetry system offers overall ease-of-use and reliable pressure measurement for industrial applications without wire.

About the author

Sandro Esposito is the Sales & Marketing Director at SignalFire Wireless Telemetry. He is responsible for business development related to process automation, which includes products and services related to distributed control systems, safety systems, programmable logic controllers, SCADA, fire & gas protection, measurement, analytical, software, system integration, industrial protocols, power systems, surveillance, remote monitoring, control panels, and HMI.Read more on : https://www.sensorsmag.com/components/monitoring-water-tower-levels-wireless-pressure-sensors