WHAT IS PLC | SCADA| HMI

PLC:- Programmable logic controller used for controlling your mechanical component electrically. Scada:-supervisory control and data acquisition. Latest update on PLC,HMI.

Thursday, July 11, 2019

Thursday, June 27, 2019

Tuesday, June 11, 2019

Friday, June 7, 2019

Saturday, August 4, 2018

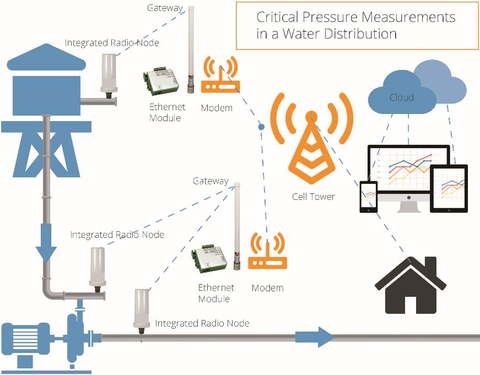

Monitoring Water Tower Levels With Wireless Pressure Sensors

Water towers are used by many communities to provide a reliable water supply during peak usage hours and power outages. These elevated structures are deliberately tall in stature to maintain sufficient pressure to deliver potable water by gravity through a pump distribution network that supplies water to homes.

As residential water pressure requirements range between 45 and 80 psi, the average height of a water tower must be around 165 ft. to deliver water at pressures between 50-60 psi. Municipalities must monitor the water distribution system to ensure proper pressure and water levels. Pressure management is critical as too high or low-pressure levels could result in inefficient system operations and damaged pumps.

Remote sensor control systems eliminate the need for operators to climb towers or travel to various locations to read gauges in monitoring pressure sensors and inputting information into a computer for analysis. However, the operating environment of the water distribution system poses challenges for wired monitoring systems.

When operating in outside environments, wired systems are susceptible to lighting strikes and ground faults that can destroy sensors and everything wired to it. Power also can be a problem for wired systems because only 120V AC is typically available at the water tanks. And as wired systems require that each sensor be wired back to the controller and connected to an interface port, maintenance on hardwired sensors can be costly because of the water tower height.

Wireless Sensing & Monitoring For Reliable Operations

A wireless remote monitoring and control system resembles the architecture of a wired system by using “air wires” instead of cabling to measure and transmit the water pressure of the water tower to a remote location. The wireless telemetry system consists of end nodes that include a radio that powers sensors, which conduct the pressure measurements for transmission to a gateway. Powered by battery, the end nodes address the challenges of using sensors in areas without a power source or when power is unstable.Serving as the central hub for receiving measurements, the gateway stores recent sensor readings in Modbus format for accessibility by a PLC in a control center or through an Internet connection. The gateway can be physically wired to a PLC/SCADA/DCS or wirelessly connected using cell modems. By using 900mHz instead of 2.4gHz, the wireless network provides for robust data transmissions through different terrain, structures, and weather conditions and operates for years in harsh environmental conditions. As nodes and other components are not physically wired, the wireless system reduces the risk of failure due to lightning strikes and ground faults that can destroy wired systems.

In figure 2 below, the Pressure Scout wireless pressure transmitter integrates a wireless radio, pressure sensor, and intrinsically-safe circuitry including a battery to serve as a cost-effective alternative to conduit, wired, and other pressure sensor solutions. This telemetry system offers overall ease-of-use and reliable pressure measurement for industrial applications without wire.

About the author

Sandro Esposito is the Sales & Marketing Director at SignalFire Wireless Telemetry. He is responsible for business development related to process automation, which includes products and services related to distributed control systems, safety systems, programmable logic controllers, SCADA, fire & gas protection, measurement, analytical, software, system integration, industrial protocols, power systems, surveillance, remote monitoring, control panels, and HMI.Read more on : https://www.sensorsmag.com/components/monitoring-water-tower-levels-wireless-pressure-sensors

What Expert Say about PLC, SCADA, and DCS Training Market 2021

PLC, SCADA, and DCS Training market report delivers comprehensive

global industry intelligence through detailed segmentation, market size

and forecasts, growth rates, market dynamics, industry structure and

developments, market situation, trends. PLC, SCADA, and DCS Training

market also gives detailed analysis of current dynamics and trends, key

market players, and strategies in the market, detailed value chain

analysis and review of growth factors essential for the existing market

players and new entrants.

Read Full Research Report at https://www.absolutereports.com/global-plc-scada-and-dcs-training-market-2017-2021-11329361

Geographical Regions: Americas, APAC, EMEA. The PLC, SCADA, and DCS Training market report analyses the market potential for each geographical region based on the growth rate, macroeconomic parameters, consumer buying patterns, demand and present scenarios in PLC, SCADA, and DCS Training industry.

Key Vendors: BASF, Geobeton, Nu-core, Wagners, Zeobond, ASK Chemicals, Milliken & Company, The Dow Chemical, and many more. The PLC, SCADA, and DCS Training market report includes company share analysis for the major companies operating in this market by major regions.

Market Driver

• Increasing adoption of Industry 4.0

• For a full, detailed list, view our report

Market Challenge

• Increased threat from open-source courseware

• For a full, detailed list, view our report

Market Trend

• Increase in personalized training

• For a full, detailed list, view our report

Read Full Research Report at https://www.absolutereports.com/global-plc-scada-and-dcs-training-market-2017-2021-11329361

Geographical Regions: Americas, APAC, EMEA. The PLC, SCADA, and DCS Training market report analyses the market potential for each geographical region based on the growth rate, macroeconomic parameters, consumer buying patterns, demand and present scenarios in PLC, SCADA, and DCS Training industry.

Key Vendors: BASF, Geobeton, Nu-core, Wagners, Zeobond, ASK Chemicals, Milliken & Company, The Dow Chemical, and many more. The PLC, SCADA, and DCS Training market report includes company share analysis for the major companies operating in this market by major regions.

Market Driver

• Increasing adoption of Industry 4.0

• For a full, detailed list, view our report

Market Challenge

• Increased threat from open-source courseware

• For a full, detailed list, view our report

Market Trend

• Increase in personalized training

• For a full, detailed list, view our report

Request for Sample of Report at https://www.absolutereports.com/enquiry/request-sample/11329361

How Will You Benefit from PLC, SCADA, and DCS Training Market Report?- Keep your data base up-to speed.

- Support your planned decision-making with final and consistent PLC, SCADA, and DCS Training market data

- Study how to exploit new technological trends

- Understand your company’s complete potential within the PLC, SCADA, and DCS Training market

- Know the competitive landscape and recognize potential new business opportunities & businesses

- What will the market size and the growth rate be in 2021?

- What are the key factors driving the global PLC, SCADA, and DCS Training market?

- What are the key market trends impacting the growth of the global market?

- What are the challenges to market growth?

- Who are the key vendors in the global PLC, SCADA, and DCS Training market?

- What are the market chances and threats faced by the manufacturers in the global market?

- What are the trending factors influencing the market shares of the Americas, APAC, and EMEA?

- What are the key outcomes of the five forces analysis of the global PLC, SCADA, and DCS Training market?

Friday, February 3, 2017

SCADA Market worth $11.16 Billion by 2020

SCADA Market worth $11.16 Billion by 2020

According to a new market research report of “SCADA Market by Components (PLC, RTU, HMI, Communication Systems), Architecture (Hardware, Software, Services), Application (Oil & Gas, Power, Water & Wastewater, Transport, Manufacturing, Chemicals), and Geography – Analysis & Forecast to 2013 – 2020” published by MarketsandMarkets, the market is expected to grow at a CAGR of 7.24% from 2014 to 2020.

• Download Informational PDF Brochure :-

http://www.marketsandmarkets.com/pdfdownload.asp?id=19487518

http://www.marketsandmarkets.com/pdfdownload.asp?id=19487518

Browse 78 market data Tables and 67 Figures spread through 266 Pages and in-depth TOC on "SCADA Market by Components (PLC, RTU, HMI, Communication Systems), Architecture (Hardware, Software, Services), Application (Oil & Gas, Power, Water & Wastewater, Transport, Manufacturing, Chemicals), and Geography – Analysis & Forecast to 2013 – 2020"

http://www.marketsandmarkets.com/Market-Reports/scada-market-19487518.html

Early buyers will receive 10% customization on reports.

http://www.marketsandmarkets.com/Market-Reports/scada-market-19487518.html

Early buyers will receive 10% customization on reports.

The supervisory control and data acquisition (SCADA) market includes programmable logic controllers (PLC), remote terminal units (RTUs), human machine interface (HMI), and communication systems. SCADA market is expected to grow in the forecasted period as there is huge potential from renewable energy sector, high investments in infrastructure for sectors such as oil and gas, power (transmission and distribution), and water and wastewater management. These are some of the factors which are driving the growth of the SCADA market. Cyber security threat is considered as an important restraint which is being faced frequently by the SCADA market.

The overall SCADA market is segmented into four major segments- components, architecture, application, and geography. All the segments are separately classified in the report. The SCADA market is expected to reach up to $11.16 billion by 2020, at an estimated CAGR of 7.24 % from 2014 to 2020.

• Speak to Analyst :-

http://www.marketsandmarkets.com/speaktoanalyst.asp?id=19487518

http://www.marketsandmarkets.com/speaktoanalyst.asp?id=19487518

Geographical split for the SCADA market is included in the report. It presents the market size of different geographies. SCADA market report divides the overall market based on the four major geographical segments- The Americas, Europe, APAC, and Rest of the world (ROW). Asia Pacific (APAC) is estimated to contribute the major share in the SCADA market, which is then followed by the Americas and Europe. Major players which are dominating the SCADA market include ABB (Switzerland), Rockwell Automation (U.S.), and Siemens (Germany).

About MarketsandMarkets

MarketsandMarkets is a global market research and consulting company based in the U.S. We publish strategically analyzed market research reports and serve as a business intelligence partner to Fortune 500 companies across the world.

MarketsandMarkets also provides multi-client reports, company profiles, databases, and custom research services. MarketsandMarkets covers thirteen industry verticals, including advanced materials, automotive and transportation, banking and financial services, biotechnology, chemicals, consumer goods, energy and power, food and beverages, industrial automation, medical devices, pharmaceuticals, semiconductor and electronics, and telecommunications and IT.

We at MarketsandMarkets are inspired to help our clients grow by providing apt business insight with our huge market intelligence repository.

Source: http://prwire.com.au/pr/65451/scada-market-worth-11-16-billion-by-2020

Subscribe to:

Posts (Atom)

GATE Exam 2020 | Syllabus, Eligibility, Application Form, Exam and Result

GATE Exam 2020 | Syllabus, Eligibility, Application Form, Exam and Result

-

PLC, SCADA, and DCS Training market report delivers comprehensive global industry intelligence through detailed segmentation, market size ...

-

Water towers are used by many communities to provide a reliable water supply during peak usage hours and power outages. These elev...